STIWA Automation

Customized Solutions for Advanced Battery Cell Manufacturing

Our offering – your advantages

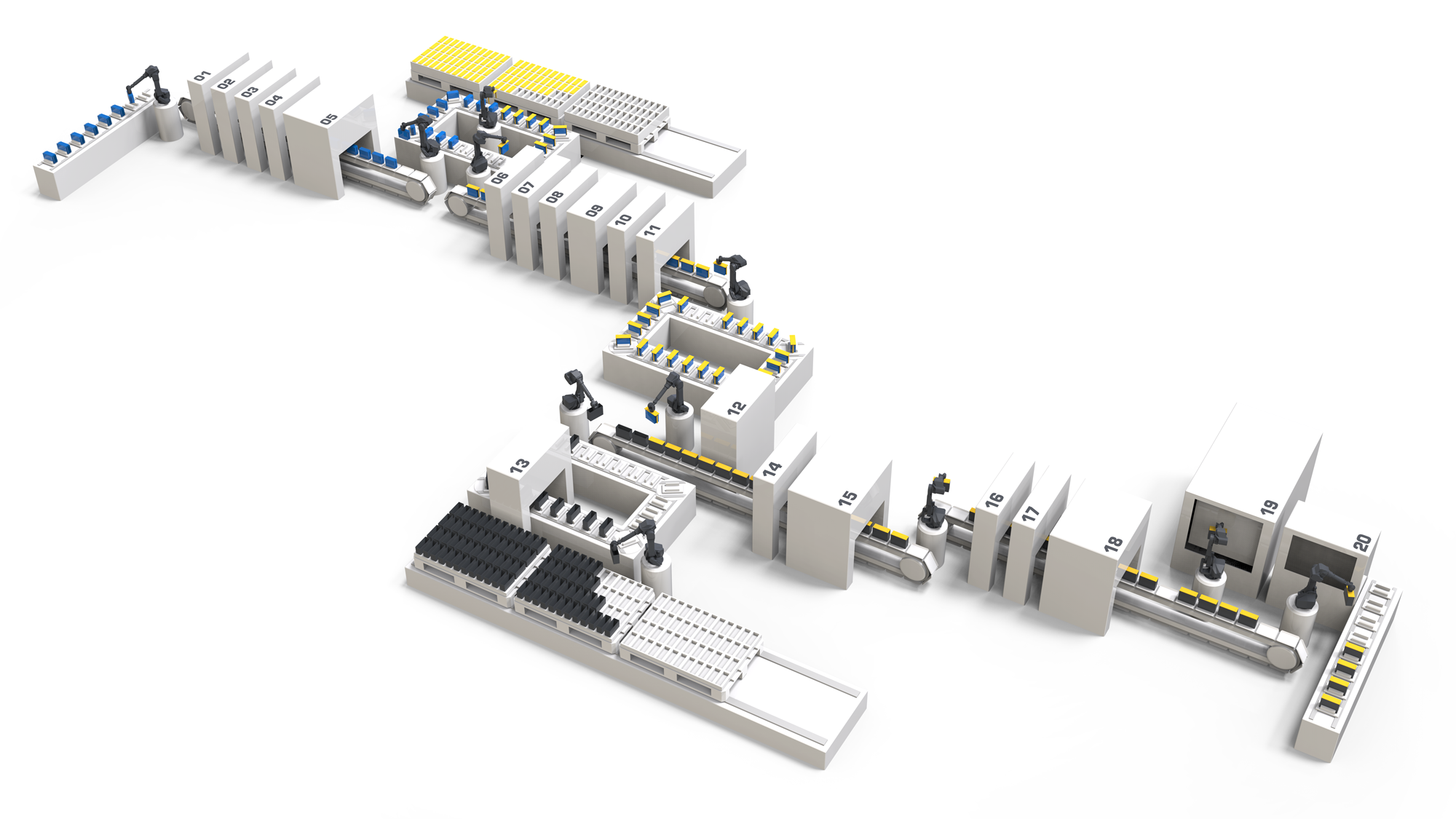

Cell Assembly

STIWA Automation offers precise and reliable solutions for each stage of cell assembly, customized to meet specific client requirements. Our expertise includes:

Hot-Pressing

Tab-Welding

Trimming

Wrapping

Tab-Lid Welding

Can-Lid Welding

Cleaning Processes

Testing Processes

Electrolyte Filling

STIWA's patented single-step electrolyte filling solution streamlines the battery cell manufacturing process. This innovative process eliminates the need for nitrogen, reducing operational complexity and costs while maintaining high quality. It can be customized to meet specific electrolyte requirements and cell designs.

Key Features

Tailor-Made Solutions: As a special machine manufacturer, STIWA provides customized solutions to meet specific client needs.

Quality Assurance: Integrated processes and testing stations ensure high-quality standards.

Process Integration: Seamless integration of cell assembly and electrolyte filling processes optimizes production flow.

High-Performance Automation: Solutions designed for high throughput and efficiency.

Controlled Micro-Environments: Specialized environments to optimize manufacturing conditions and energy consumption, tailored to specific process requirements.

About us

STIWA Automation specializes in providing tailor-made, integrated solutions for battery cell manufacturing. As a special machine manufacturer, we focus on enhancing quality, efficiency, and performance through customized automation solutions and controlled micro-environments, supporting the advancement of battery technology.